RFID tamper tag,COB NFC tag, micro size

Security solution for skin care packing

Confidential documents,service authrization

Famouse brand protection, encryption ticket,

Cosmatic asset trace,Transportation control

Access control,liquor & wine inventory tracking

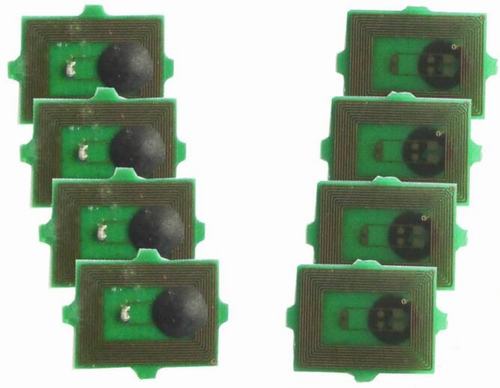

Hard Tag 5*6 mm PCB Micro Tag

Place of origin : Fujian China ( mainland )

Brand name : Xminnov ODM or OEM

Tag Size 5*6 mm or customized

Chip: Ntag 213

Frequency : 13.56 MHz (860-960 MHz)

Protocol: 14443

International Standard: FCC, ETSI

Conduct Material: Aluminum Etching / 9um thickness

Substrate: PET of 50um thickness

产品属性:可选的防篡改,Brittle antenna, Destructive aluminum etching, Fragile copper etching, Ink of silver Printing antenna based

Product Feature: Function of Non-transfer, Fragile,Tamper Evident, Anti-counterfeiting, non-transferable,break on antenna, break on chip,one time use, Disposable, Destructive IP Level, Waterproof, UV IR rays resistant, heat or temperature resistant and chemical resistant

Small and durable for heavy industry and outdoor applications.

Survives long term use in harsh outdoor environments.

Suited for industrial asset management and equipment rental applications.

The on metal RFID tags overcome some of the problems traditional RFID tags suffer when near metal, such as detuning and reflecting of the RFID signal, which can cause poor tag read range, phantom reads, or no read signal at all.

High label recognition sensitivity for simultaneous multi-tag recognition

The chip can be read and written more than 100,000 times, and the service life can reach 10 years.

Assets warehouse management: The tags are installed on the pallets to record the inbound and outbound data of the forklift pallets of the forklift, and realize the processing and query statistics of data such as storage, delivery, and inventory.

Production tracking management: The label can be fixed to the pallet, the production data and production process can be tracked and managed, and the production data and processes of the products contained in the pallet can be tracked throughout the production process for tracking the product life cycle.

Gas cylinder inspection management: Identify and record the key process points of cylinder maintenance, and track and manage the cylinders through the database.

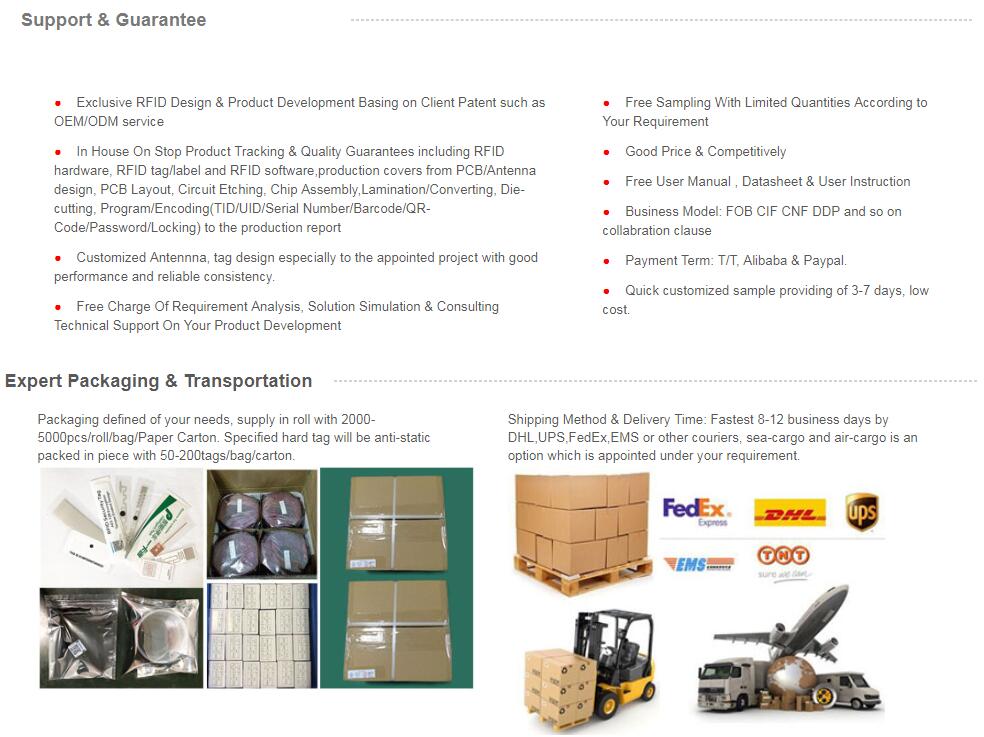

Gun management: It mainly tracks and identifies the use of firearms such as rifle retrieving and returning, and can monitor the number of guns in the gun cabinet, position information and abnormal alarms in real time.